Dynamic O2 / CO2 control

Limitless protocol possibilities

Physiological O2 / CO2 simulation

Pathologic O2 / CO2 modeling

Accountability

Automated control

PC interface

Intermittent hypoxia in vitro models

Hypoxic preconditioning cell models

DUAL CHAMBER / DUAL GAS

The OxyCycler C42 is a unique dual channel/dual gas controller for incubators and C-Chambers. Oxygen and carbon dioxide control is managed via independently programmable channels for optimum control. No other instrument has such a fine simulation of dynamic exposure. Applications of the OxyCycler C42 incubator controller include intermittent hypoxia, graded hypoxia, and timed hyperoxia.

OXYGEN CONCENTRATION

Changes in O2 concentration do affect the physiology of the cells in vivo and now you can simulate these O2 dynamics in vitro. Complex, multi-setpoint oxygen profiles can be arranged to recreate conditions such as heart attack, strokes and epilepsy. When a profile is made, it can be reproduced to develop these dynamic models. The OxyCycler C42 is the predominant instrument capable of meeting these demands.

CREATE ANY PROFILE

The OxyCycler C42 incubator controller is a unique instrument that offers sophisticated O2 and CO2 profiling. It easily creates any profile needed between 0.1-99.9% O2 and 0.1-20.0% CO2 independently and in multiple chambers simultaneously. The OxyCycler C42 enables multiple setpoints for any length of time, over any rate of change between these setpoints with any number of cycles and setpoints. The OxyCycler C42 makes complex oxygen cycling easy.

MANY FEATURES

A standard OxyCycler C42 comes with computer software for easy interface, real time trend charting, data logging, and remote operation. Since the OxyCycler C42 works with semi-sealed subchambers the profiles are normobaric. N2 and O2gas infusions displace the chamber gas while internal and external pressure remain equilibrated.

Installation Schematic

1. Set OxyCycler C42 on or near host chamber and plug it in.

2. Hook up sensor and gas infusion tube and insert both into the chamber.

3. Hook up gas supply.

How It Works

The OxyCycler C42 is used predominantly as a dual subchamber system for experiment and control. These isolating subchambers are placed within a third party CO2 (only) or thermal incubator. The OxyCycler C42 is supplied by three control gases: O2, N2, and CO2 and fits any of our standard subchambers. The OxyCycler C42 connects to the subchamber by flexible umbilicals, which consist of electrical and pneumatic leads, that are inserted into the incubator.

The pod component of the OxyCycler C42 is uniquely designed to isolate the critical cell environment which can get contaminated from the sensing mechanisms for monitoring the gases in the chamber. This isolation is accomplished by putting the sensors inside the pod and pumping a sample from the chamber to the pod, then past the sensors back into the chamber. This side stream sampling starts with the sterile filter and ends with a sterile filter, minimizing the chance of the chamber contaminating the sensor loop. Likewise, if there ever was a contamination in the sensor loop it wouldn’t contaminate the chamber.

OPERATION IS SIMPLE

Cells are dynamic entities and the OxyCycler C42 is the first controller to provide dynamic O2 and CO2 to keep up with the needs of cells. Dynamic exposures are programmed with a series of setpoints that can change, be stored and re-run with the click of a mouse.

INCUBATOR PORT

The OxyCycler C42 sits outside your incubator and couples via umbilicals to actuator pods attached to the incubator subchambers within. These pods contain the sensors and gas infusion nozzle as well as mounting hardware. Our c-chambers have specially designed cut-outs to mount the actuator pods. The OxyCycler C42 remotely senses the active gas concentrations in the chambers and infuses O2/CO2 to increase or N2 to decrease to the programmed setpoints.

USE ANY GAS SUPPLY

OxyCycler C42 conveniently utilizes gas from any source. Best supply depends on consumption. Compressed gas is best in low consumption applications. Generator is best in high consumption applications. Liquid is best in between.

SAVES GAS AND MONEY

Chamber gas consumption varies widely, but in every case the OxyCycler C42 always and absolutely minimizes gas consumption. It’s maximally efficient! Gas costs are reduced to absolute minimum.

Hypoxic stress can model components of many severe diseases such as heart attacks, strokes, asthma, or epilepsy. Frequency, duration and degree of drops are all adjustable.

Cells destined for implantation will experience hypoxia and may be better prepared if they are conditioned to it before implantation. Ischemia may also be protected by conditioning. The OxyCycler C42 can easily run any preconditioning profile.

Model step reduction in oxygen, similar to altitude acclimation, to gradually condition cells for hypoxic upregulation of gene expression. The rate of change between any two levels is adjustable and repeatable. The duration at any given level is adjustable and repeatable.

Sudden increases in oxygen can cause cell damage. The OxyCycler C42 allows modeling toxicity of oxygen in any cell culture, similar to toxicity from recreational oxygen inhalation by athletes, therapeutic oxygen administration in critical care units, and other sudden exposures to high oxygen. The rate of oxygen increase can be adjusted to change faster to overwhelm antioxidants, or change slower to condition for antioxidants.

ELECTRICAL POWER: 12VDC, 6.6AMP

CONTROL RANGE: O2: 0.1-99.9% , CO2: 0.1-20%

ACCURACY: O2: ±1% at constant temperature and pressure ±2%

at entire temperature range. CO2: ±5% or .1%, whichever is greater.RESOLUTION: 0.1%

OXYGEN SENSOR: Various application specific sensors are available

GAS SOURCE: Compressed gas tanks, liquid carboys (from headspace) or generators.

GAS SUPPLY: Pressurized O2, CO2 and/or N2

GAS SUPPLY LINE: 1/4” ID hose, pressure rated to 25 PSIG

GAS SUPPLY LINE PRESSURE: 0-25 PSIG

GAS INFUSION RATE: 0-12 SCFH

GAS CONSUMPTION: Depends on (1) size and leakiness of host chamber, (2) frequency and duration of opening chamber doors and (3) oxygen level controlled

GAS SUPPLY HOSE FITTING: 1/4” ID

UMBILICAL LENGTH: 12 ft

SENSOR CABLE LENGTH: 12 ft

SENSOR CABLE DIAMETER: 6mm

ALARM OUTPUT: External Alarm

ALARM MODES: Process high, process low, deviation high, deviation low, and deviation band.

WEIGHT: 22lbs (controller only)

CONTROLLER DIMENSIONS: 9”H, 17”W, 16”D

ACTUATOR POD DIMENSIONS: 4.375”H, 7.125”W, 3.75”D

Sensor Operational Parameters

HOST CHAMBER TEMPERATURE: 5-40°C

HOST CHAMBER HUMIDITY 5-95%, Non-condensing

Front Panel

1. Controller: Bright digits display process values and provides manual user interface to control gas infusion.

2. Bleed Valves and Barbs: Bleeds gases out of gas supply lines. Calibration cup for sensor attaches here.

3. ZERO Calibration Gas Flowmeter: Used for calibration.

4. SPAN Calibration Gas Flowmeter: Used for calibration.

5. Needle Valves for Chamber 1: Sets infusion rate of control gases in each chamber to accommodate different dynamics. Can manually override controller to shut off gas.

6. Needle Valves for Chamber 2: Sets infusion rate of control gases in each chamber to accommodate different dynamics. Can manually override controller to shut off gas.

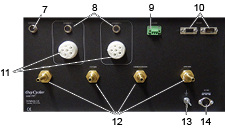

Back Panel

7. Accessory Receptacle: 10 Pin Receptacle is for connecting optional accessory units.

8. Communications Cables: These cables relay information for the sensors and gives power to the sample draw pump.

9. Alarm Receptacle: Connect an appropriate alarm to this jack.

10. RS485 Communications Cables: One cable attaches to a computer and the other cable attaches to another unit, to allow communication with the computer (if applicable).

11. Umbilicals: Delivers infusion and calibration gas from the unit to the chamber. To connect, push the connector onto the receptacle.

12. Supply Gas Hose Barbs: Barbs for 1/4 inch I.D. hose from gas sources. Handles pressure up to 40 PSIG.

13. Ground Stud: For grounding the unit to protect from electric damage.

14. Power Receptacle: 12VDC power supply connects here.

Altitude / Aerospace

Blood / Hematology

Cancer / Tumor Biology

Carbon Monoxide

Cardiovascular

Cell Analysis

Cell Cycle / Cell Death

Cell Imaging

Circadian Rhythm

Development

Endocrine / Diabetes

Exercise

Gastrointestinal

Genetics / Genomics

Hepatocyte

HIF / Hypoxia

Hypercapnia

Immunology

In Vitro Drug Discovery

In Vitro Toxicology

Intermittent Hypoxia

Kidney

Metabolism / Mitochondria

Neuroscience

Nitric Oxide

Orthopaedic / Musculoskeletal

Oxygen Sensing

Pulmonary

Physiologic Oxygen / Physioxia

Redox / ROS / Oxidative Stress

Respiratory Control / Therapeutic Hypoxia

Sleep Apnea

Stem Cell

Tissue Engineering / 3D Culture / Organoid

Vascular Research

Vision / Ophthalmology

Forgalmazott termékeink gyártói - keressen gyártó szerint a logóra kattintva

Forgalmazott termékeink gyártói - keressen gyártó szerint a logóra kattintva