Precise Automated Exposures of CO and NO

Dynamic or Static Exposures

Simulate Physiologic and Pathophysiologic conditions

Unprecedented CO Induced Phenotypes

Unprecedented NO Induced Phenotypes

ADVANCED GASOTRANSMITTER INCUBATION

Carbon monoxide and nitric oxide are both important gasotransmitters with a wide variety of similar, overlapping, and different functions. Now it is possible to study them independently or simultaneously in cell culture without the difficulty of chemical donors. The OxyCycler GT4181CN is the only dual gasotransmitter cell culture system providing control of both CO and NO. It creates the ultimate incubator accessory when controlling CO and/or NO in a subchamber culture system.

UNLIMITED PROGRAMMED, DYNAMIC EXPOSURES

Consisting of a GT41 which provides the common O2, CO2, and RH control, and the modular GT81CN piggyback controller, which provides not only the CO and NO range control but also NO2 limiting, the combo can create virtually any type of dynamic or static exposure your cells might need.

MODULAR FLEXIBILITY

The controller is compatible and will fit any standard size C-Chamber. The entire OxyCycler GT4181CN CO/NO cell culture system will fit any existing incubator.

Installation Schematic

OxyCycler GT4181CN Culture System. Controls dynamic or static O2, CO2, CO and NO, and limits RH and NO2 in subchamber. Supply gases to GT41 required: Oxygen, Nitrogen, Carbon Dioxide. Calibration gas to GT41 required: certified pre-mix of 10% CO2 in balance oxygen. Supply gases to GT81CN: non-certified pre-mix of 10000ppm CO in balance nitrogen, and non-certified pre-mix of 1000ppm NO in balance nitrogen. Calibration gases to GT81CN required: certified pre-mix of 300ppm CO in balance nitrogen, certified pre-mix of 30ppm NO in balance nitrogen, and certified pre-mix 10ppm NO2 in balance nitrogen.

Configuration

The OxyCycler GT4181CN is a combination controller consisting of a GT41 mother controller and the GT81CN piggyback controller working in tandem. It is the ultimate for CO and NO gasotransmitter research. The GT41 controls core O2 and CO2 levels in dynamic or static states and limits RH, while the GT81CN controls 0-400 ppm CO in dynamic or static exposures, and 0-40 ppm NO in dynamic or static exposures, while limiting NO2 from accumulating past critical levels.

How It Works

Hot swap multipod adapter plate provides microbial barrier filters between cells culturing in the subchamber and all of the sensors and mechanisms that control O2, CO2, RH, CO, NO/NO2 and temperature. Hot swap multipods provide upgrade flexibility and immediate, easy maintenance. A pump draws a sample from the controlled atmosphere and passes by all sensors and returns to chamber through disposable microbial barrier filters. Appropriate gases are infused as necessary by controllers through terminal, microbial barrier filters. Small fan homogenizes gases throughout chamber and can be easily removed, sterilized and replaced.

Controller sits outside the incubator and umbilicals extend through port hole on the incubator and connect to Hot Swap Minipod Assembly inside the incubator.

Operated by a computer and powerful software allows user to program any type of exposure with all variables and repeat those exposures with the click of a mouse. Profiles can be created, stored and recorded 24 hrs a day/7 days a week.

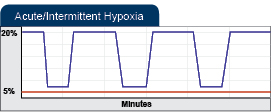

Hypoxic stress can model components of many severe diseases such as heart attacks, strokes, asthma, or epilepsy. Frequency, duration and degree of drops are all adjustable.

Model step reduction in oxygen, similar to altitude acclimation, to gradually condition cells for hypoxic upregulation of gene expression. The rate of change between any two levels is adjustable and repeatable. The duration at any given level is adjustable and repeatable.

Cells destined for implantation will experience hypoxia and may be better prepared if they are conditioned to it before implantation. Ischemia may also be protected by conditioning. The OxyCycler GT4181CN can easily run any preconditioning profile.

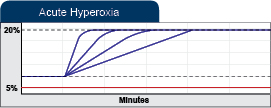

Sudden increases in oxygen can cause cell damage. The OxyCycler GT4181CN allows modeling toxicity of oxygen in any cell culture, similar to toxicity from recreational oxygen inhalation by athletes, therapeutic oxygen administration in critical care units, and other sudden exposures to high oxygen. The rate of oxygen increase can be adjusted to change faster to overwhelm antioxidants, or change slower to condition for antioxidants.

SYSTEM SPECIFICATION

ELECTRICAL POWER: 12 VDC at 6.66A (Power Supply Specifications), Expected current draw around 3.7A.

CONTROL RANGE: O2: 0.1-99.9%, CO2: 0.1-20.0%, CO: 0-400 PPM, NO: 0-50 PPM

ACCURACY: O2: ±1% at constant temperature/pressure, ±2% over entire temperature range. CO2: ±5% of measurement or 0.1% CO2. Temperature: ±0.6°C. Relative Humidity: ±3% RH between 0-40°C. CO: varies based on calibration for customer protocol. NO: varies based on calibration for customer protocol

CARBON DIOXIDE SENSOR: Infrared sensing

CARBON MONOXIDE SENSOR: Electro-galvanic fuel cell

NITRIC OXIDE SENSOR: Electro-galvanic fuel cell

NITROGEN DIOXIDE SENSOR: Electro-galvanic fuel cell

GAS SOURCE: Compressed gas tanks, liquid carboys (from headspace) or generators

GAS SUPPLY: Pressurized O2, CO2, N2, O2/CO2 SPAN mix, CO, CO SPAN mix, NO, NO SPAN mix. Customer should consider protocol when ordering SPAN gases. Appropriate CO/NO volume and concentration to be determined by lab safety officer.

GAS SUPPLY LINE PRESSURE: 0-25 PSIG

GAS CONSUMPTION: Depends on (1) size and leakiness of host chamber, (2) frequency and duration of opening chamber doors and (3) gas level controlled

UMBILICAL LENGTH: 12 ft

UMBILICAL DIAMETER: 1/16” ID

SENSOR CABLE LENGTH: 12 ft

SENSOR CABLE DIAMETER: 6mm

ALARM OUTPUT: Global Alarm Output and Audible, External Alarm system

ALARM MODES: Process High, Process Low, Deviation High, Deviation Low, Deviation Band

WEIGHT: 22 Lbs

CONTROLLER DIMENSIONS: 9”H, 17”W, 15”D

REMOTE MONITOR POD DIMENSIONS: 4.25”H, 7.0625”W, 4.25”D

SENSOR OPERATIONAL PARAMETERS

HOST CHAMBER TEMPERATURE: 5-40°C

HOST CHAMBER HUMIDITY 15-90%, Non-Condensing

GT81CN

GT41

1. Bleed Valves and Barbs: Bleeds gases out of gas supply lines. Calibration cup for sensor attaches here.

2. Controller: Bright blue digits on black back ground. Continuously displays current control gas level, control status, and alarm status in all chambers. Displays menu items and settings during programming.

3. Alarm: Will sound if Ambient gas monitor detects unsafe levels.

4. ZERO Calibration Gas Flowmeter: Used for calibration.

5. SPAN Calibration Gas Flowmeter: Used for calibration.

6. Needle Valves: Sets infusion rate of control gases in each chamber to accommodate different dynamics. Can manually override controller to shut off gas.

7. Accessory Receptacle: 10 Pin Receptacle is for connecting optional accessory units.

8. Communications Cable Jack: This cable relays information for the sensors.

9. Monitor Pod Umbilical: Flexible umbilical connects remote monitor pod to back panel. Semi-swivel connectors at both ends allow 360° orientation. Some models are hard welded; function is the same.

10. Alarm Receptacle: Connect an appropriate alarm to this jack.

11. RS 485 Connections: One cable attaches to a computer and the other cable attaches to another unit, to allow communication with the computer (if applicable).

12. Pump Connection: This 3 pin receptacle supplies power to the Mini Pod Pump.

13. Supply Gas Hose Barb: Barbs for 1/4 inch I.D. hose from gas sources. Handles pressure up to 40 PSIG.

14. Span Mix Barb: Barb for 1/4 inch I.D. hose from gas source.

15. Ground Stud: For grounding the unit to protect from electric damage.

16. Power Receptacle: 12VDC power supply connects here.

17. Monitor Pod Umbilical: Flexible umbilical connects remote monitor pod to back panel. Semi-swivel connectors at both ends allow 360° orientation. Some models are hard welded; function is the same.

Altitude / Aerospace

Blood / Hematology

Cancer / Tumor Biology

Carbon Monoxide

Cardiovascular

Cell Analysis

Cell Cycle / Cell Death

Cell Imaging

Circadian Rhythm

Development

Endocrine / Diabetes

Exercise

Gastrointestinal

Genetics / Genomics

Hepatocyte

HIF / Hypoxia

Hypercapnia

Immunology

In Vitro Drug Discovery

In Vitro Toxicology

Intermittent Hypoxia

Kidney

Metabolism / Mitochondria

Neuroscience

Nitric Oxide

Orthopaedic / Musculoskeletal

Oxygen Sensing

Pulmonary

Physiologic Oxygen / Physioxia

Redox / ROS / Oxidative Stress

Respiratory Control / Therapeutic Hypoxia

Sleep Apnea

Stem Cell

Tissue Engineering / 3D Culture / Organoid

Vascular Research

Vision / Ophthalmology

Forgalmazott termékeink gyártói - keressen gyártó szerint a logóra kattintva

Forgalmazott termékeink gyártói - keressen gyártó szerint a logóra kattintva