Incubators

Gloveboxes

Refrigerators

Animal Cages

Plant Chambers

Plastic Bags

Ice Boxes

Tents

Etc.

VERSATILE CO2 TOOL

The new ProCO2 120 is a versatile, compact carbon dioxide controller for people who do CO2 sensitive work. The ProCO2 120 fits in virtually any chamber, and makes it easy to control the CO2 level inside that host chamber.

PHYSIOLOGIC OR AMBIENT RANGES

Controller set point can be anywhere from 0.1-20.0% CO2 for most physiologic concentrations. Alternatively, low level, high resolution set points from 10-10,000 ppm can be limit-controlled over ambient range with a version of this controller.

WORKS IN ANY CHAMBER

The ProCO2 120 compact CO2 controller fits inside any semi-sealable enclosure. What ever size, shape, rigidity, or isolation, most chambers can be fitted in minutes. The ProCO2 120 works from outside the host chamber by remotely sensing the CO2 inside the chamber. It infuses CO2 gas to raise the carbon dioxide levels, or nitrogen to displace and lower the CO2 levels.

CONTROL IS EFFICIENT

The ProCO2 120 gains feedback from the CO2 sensor, in order to precisely regulate gas infusion according to the set point. No gas is ever wasted with this compact CO2 controller.

OPERATION IS SIMPLE

CO2 is quickly taken to set point and held there indefinitely. Any disturbances are instantly detected and corrected immediately. Calibration and gas supply must be checked once in a while. All else is automatic.

HANDLES ANY CO2 CONTROL JOB

• Where ambient air CO2 is too low or too high, it can provide any other level you need up to 20%.

• Where ambient is not air, it can restore and maintain air equivalent CO2.

• Where CO2 consumptive or generative processes need to be countered, it can hold CO2 stable.

Run the ProCO2 120 compact CO2 controller continuously year-round, or on occasion as needed. No other CO2 controller offers so much value.

Direct insertion of sensor/tubing (shown on incubator)

Control via Adapter Plate (shown on BioSpherix A-Chamber)

Subchamber via Adapter Plate (shown on BioSpherix C-Chamber)

ProCO2 120 can control any semi-sealable chamber by one of the methods shown above, installation may vary based on chamber.

Installation

1. Set ProCO2 120 on or near host chamber and plug it in.

2. Hook up sensor and gas infusion tube and insert both into chamber.

3. Hook up gas supply.

How It Works

From outside the host chamber, the ProCO2 120 works by remotely sensing the oxygen concentration inside the chamber and infusing either nitrogen to lower it or carbon dioxide to raise it.

Installation is easy. Simply insert sensor and nozzle of infusion tube into chamber through any convenient passageway. Doors, windows, sample ports, access ports, holes (built-in or custom-drilled) all work.

FRONT PANEL INTERFACE

All operators are conveniently located on the front panel. All connections are on the back panel, out of the way. Carbon dioxide concentration at sensor continuously displays in bright green digits that can easily be read from across the room. Manual switch for gas provides convenient shut off. It saves gas when the chamber door is open. Just don’t forget to turn it back on! The alarm buzzer also has a manual switch.

Gas

USE ANY GAS SUPPLY

The ProCO2 120 conveniently utilizes gas from any source. Best supply depends on consumption. Compressed gas is best in low consumption applications. Generator is best in high consumption applications. Liquid is best in between.

SAVES GAS AND MONEY

Chamber gas consumption varies widely, but in every case the ProCO2 120 always and absolutely minimizes gas consumption. It’s maximally efficient! Gas costs are reduced to absolute minimum.

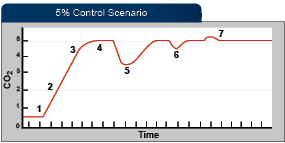

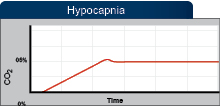

1. No control yet. Chamber CO2 is ambient air CO2 (0%).

2. Control starts. Control gas is CO2 and the ProCO2 120 immediately infuses it to raise chamber levels of CO2 up.

3. CO2 is taken to setpoint. How fast depends on infusion rate. Infusion rate is adjustable. The higher the infusion rate, the faster to setpoint. Gas consumption in this phase is mostly a function of chamber size. The larger the chamber, the more gas it takes.

4. Steady-state control at setpoint is established. Infusion of control gas exactly matches chamber leakage to hold CO2 level constant. Gas consumption here is mostly a function of chamber leakage. The leakier the chamber, the more gas it takes.

5. Door of chamber is suddenly opened and closed. Steady-state is disrupted. In-rush of air is immediately detected and chamber CO2 is promptly returned to setpoint. Gas consumption depends on how wide and how long the door was opened. The more it’s disrupted, the more gas it takes to get back to set point.

6. Door suddenly unlatches. Leakage goes up, but the ProCO2 120 compensates and immediately re-establishes steady set point. Gas consumption goes up dramatically, but CO2 is kept at set point. Consumption increases in proportion to leakage.

7. Door gets shut tight. Leakage goes back down to normal. The ProCO2 120 compensates by drifting back to setpoint and re-establishes steady-state at setpoint. Gas consumption goes back down to normal levels, while CO2 stays put.

NORMOBARIC FEEDBACK CONTROL

ProCO2 120 works in semi-sealable chambers. It controls chamber carbon dioxide by infusing it, displacing some of the current gaseous contents. Pressure inside the chamber stays the same as pressure outside.

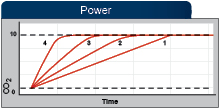

Reaching a setpoint is a logarithmic process. The further away from ambient the setpoint is, the slower it goes. But closed-loop control is efficient. By constantly monitoring chamber carbon dioxide, it promptly gets to setpoint. It responds immediately to correct any disturbance. It automatically adjusts to different loads. And in the process, it uses the least amount of gas possible!

Power is a function of infusion rate of control gas. The higher the infusion rate, the faster to setpoint. Above: infusion rate #4>#3>#2>#1. Infusion rate is a function of control gas supply pressure. The higher the pressure, the higher the infusion rate. Maximum 25 PSIG provides 35 SCFH.

Hypercapnia is a relative term that means excess concentration of CO2. The ProCO2 120 can create hypercapnia by infusing the CO2 into the chamber until it reaches the setpoint and holding it there.

Hypocapnia is a relative term that means a lesser amount of CO2 concentration (relevant to cell culture). In cell culture, 5% CO2 is pretty standard practice. The ProCO2 can create hypocapnia by infusing the CO2 to a specific setpoint.

Specifications

ELECTRICAL POWER: 12 VDC at 2.5A

CONTROL RANGE: 0.1-20% carbon dioxide (depending on the power/ load balance)

ACCURACY: ±.3% (@0%) to ±.7% (@20%) at 25°C and 1013hPa

RESOLUTION: 0.1%

CARBON DIOXIDE SENSOR: various application specific sensors are available.

GAS SOURCE: compressed gas tanks, liquid carboys (from headspace), or generators.

GAS SUPPLY: pressurized CO2 or N2

GAS SUPPLY LINE: 1/8” I.D. hose pressure rated to 25 PSIG.

GAS SUPPLY LINE PRESSURE: 1-25 P.S.I.G.

GAS INFUSION RATE: 0-25 S.C.F.H.

GAS CONSUMPTION: depends on (1) size and leakiness of host chamber, (2) frequency and duration of opening chamber doors, and (3) carbon dioxide level controlled.

GAS SUPPLY HOSE FITTING: 1/8” hose barb.

INFUSION TUBING HOSE FITTING: 1/8” ID hose barb.

INFUSION TUBING DIAMETER: 1/4” O.D. x 1/8” I.D. (special tubing sizes available).

INFUSION TUBING LENGTH: 10 ft. (custom lengths available).

SENSOR CABLE LENGTH: 6’8”

SENSOR CABLE DIAMETER: 6mm.

ALARM OUTPUT: audible 40dB alarm and visible flashing indicator.

ALARM MODES: process high, process low, deviation high, deviation low, deviation band.

WEIGHT: .7 lbs (Controller Only)

DIMENSIONS: 1.5”H x 3.5”W x 7”D

Sensor Operational Parameters

HOST CHAMBER SIZE: depends on the chamber gas dynamics and carbon dioxide level controlled.

HOST CHAMBER TEMPERATURE: -20-50°C (depending on sensor)

HOST CHAMBER CO2: 0-99% (depending on sensor)

HOST CHAMBER HUMIDITY: 0-100% R.H. Non-Condensing

Optional:

Windows® based software package that provides trend plotting, data logging, and remote operation via RS connection to your PC. Multiple ProCO2 can be daisy chained via optional RS-485 interface.

Front Panel

1. Bleed Valve: Bleeds gas out of gas supply line. Used for calibrating sensor and depressurizing gas supply.

2. Control Indicator Light: Flashes when gas is infused.

3. Digital Display: Bright green 0.4 inch digits. Continuously displays CO2 concentration at sensor, unless pre-empted by other operations. Displays menu items and settings during programming.

4. Alarm Indicator Light: Flashes when alarm output is actuated.

5. Gas Switch: Manually overrides controller to shut off gas.

6. Alarm Switch: Manually overrides controller to shut off alarm.

7. Touch Keys: 3 amply spaced tactile keys for setting configuration and control parameters.

8. Bleed Barb: 1/8” hose barb where gas bleeds out from bleed valve. Calibration tubing for sensor attaches here.

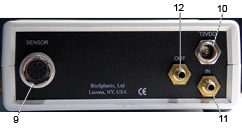

Back Panel

9. Sensor Input Jack: Locking sensor cable connects here. Finger tightened locking nut on cable plug secures it.

10. Power Receptacle: 12VDC power supply connects here.

11. Supply Gas Hose Barb: Barbs for 1/8′′ I.D. hose from gas sources. Handles pressure up to 25 PSIG.

12. Control Gas Outlet: Brass 1/8” hose barb where infusion tubing into host chamber connects.

Altitude / Aerospace

Blood / Hematology

Cancer / Tumor Biology

Carbon Monoxide

Cardiovascular

Cell Analysis

Cell Cycle / Cell Death

Cell Imaging

Circadian Rhythm

Development

Endocrine / Diabetes

Exercise

Gastrointestinal

Genetics / Genomics

Hepatocyte

HIF / Hypoxia

Hypercapnia

Immunology

In Vitro Drug Discovery

In Vitro Toxicology

Intermittent Hypoxia

Kidney

Metabolism / Mitochondria

Neuroscience

Nitric Oxide

Orthopaedic / Musculoskeletal

Oxygen Sensing

Pulmonary

Physiologic Oxygen / Physioxia

Redox / ROS / Oxidative Stress

Respiratory Control / Therapeutic Hypoxia

Sleep Apnea

Stem Cell

Tissue Engineering / 3D Culture / Organoid

Vascular Research

Vision / Ophthalmology

Forgalmazott termékeink gyártói - keressen gyártó szerint a logóra kattintva

Forgalmazott termékeink gyártói - keressen gyártó szerint a logóra kattintva