Full range O2 control

Independent CO2 control

Contamination resistant

Forced gas homogenization

Combines the best features of O2 and CO2 controllers in one unit

Hypoxia or Hyperoxia in vitro / in vivo

Physiologic oxygen for cell research

The ProOx C21 is a practical tool for researchers experimenting with cell cultures where both O2 and CO2 control and monitoring is needed. It controls both gases in one convenient unit.

FITS MOST CELL CULTURE CHAMBERS

The ProOx C21 fits and controls most bench-top incubators and a variety of common cell culture chambers. The ProOx C21 is compatible with the BioSpherix C-Chamber (subchamber). The compact O2/CO2 controller is installed quickly and easily.

PHYSIOLOGIC AND PATHOLOGIC O2

Cells normally exist in low oxygen micro-environments and thus need to be modeled in vitro. The ProOx C21 is able to simulate any low oxygen environment. The compact O2/CO2 controller can also supply elevated oxygen concentration for hyperoxic conditions. It independently controls CO2 for correct pH maintenance. The gases are infused and controlled to the user programmed set point.

CONTROL IS EFFICIENT

Feedback from the custom designed O2 and CO2 sensors tells the ProOx C21 the time and amount of gas to infuse. Thus, no gas is ever wasted. Recovery after access is especially rapid.

DECREASES RISK OF CONTAMINATION

The remote gas pod has a unique design that is resistant to initial and inadvertent cross-contamination. The pod works by isolating the potential source of the contamination, using disposable microbial barriers on all parts of the gas delivery system. If the the microbial barrier eliminates the risk of cross infection on the return. All of the controlled, infused gas is sterile filtered. The microbial barrier filters are user-replaceable. All contact surfaces of the compact O2/CO2 controller are easily decontaminated.

HANDLES ANY JOB

• Where ambient conditions are not correct, the ProOx C21 can provide any other level of O2 or CO2 you need.

• Where ambient atmosphere is not air, the ProOx C21 can restore and maintain air-equivalent O2.

• Where O2 or CO2 consumptive or generative processes need to be countered the ProOx C21 can hold both work continuously year-round, or on occasion as needed.

Installation

1. Set ProOx C21 on or near host chamber and plug it in.

2. Hook up sensor and gas infusion tube and insert both into the chamber.

3. Hook up gas supply.

How It Works

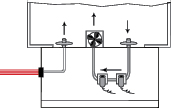

From outside the host chamber, the ProOx C21 works by remotely sensing oxygen and carbon dioxide inside the chamber and infusing gas to control both. Oxygen and carbon dioxide are infused to raise each of their levels and nitrogen is infused to lower them through displacement. Once the initial gas reaches its set point, the second quickly follows. The accessory pod that attaches to the sub chamber contains the gas sensors. These sensors are isolated behind microbial barriers and also isolated from the controlled environment of the culture chamber. The pod also provides the infused, sterile, filtered gas. A flexible conduit (umbilical) connects the controller to the pod.

The pod component of the ProOx C21 is uniquely designed to isolate the critical cell environment (which can get contaminated) from the sensing mechanisms for monitoring the gases in the chamber. This isolation is accomplished by putting the sensors inside the pod and pulling a sample of gas from the chamber to the pod, then through the sensors back into the chamber. This side stream sampling starts with a sterile filter and ends with a sterile filter, so that if there was contamination it wouldn’t get past the sensors.

Front Panel Interface

All operations are conveniently located at the front of the panel and all connections are located at the back and out of the way allowing for less interference and increasing usability for cell culture research and development.

O2 and CO2 concentration sensor readings are displayed in bright green numbers to be continuously and easily monitored from across the lab.

Manual switch for gas provides a convenient shut off thus saving gas when chamber door is opened. An alarm buzzer, also manual, will remind you if you have forgotten to turn the gas back on.

USE ANY GAS SUPPLY

Conveniently utilizes gas from any source. Best supply depends on consumption. Compressed gas is best in low consumption applications. Generator is best in high consumption applications. Liquid is best in between.

SAVES GAS AND MONEY

Chamber gas consumption varies widely, but in every case the ProOx C21 always and absolutely minimizes gas consumption. It’s maximally efficient! Gas costs are reduced to absolute minimum.

At time (1) user opened and closed door briefly for access. Room air rushed in and took both O2 and CO2 away from setpoint. However, automatic feedback immediately responded and returned both gases back to setpoint. At time (2) user unlatched door but before he could open it became distracted and forgot to re-latch, thus increased chamber leakage. Again however, automatic feedback control quickly adjusted and re-established setpoints. Obviously gas consumption increased to accommodate the increased load but the integrity of the experiment was maintained.

CONTROL GAS IS NITROGEN

Setpoints are 0.1-20.7% oxygen. The lower the set point, the more time and nitrogen it takes to reach and hold the setpoint.

Hypocapnia is a relative term to cells that means a lesser amount of CO2 concentration. The ProOx C21 can create hypocapnia in a CO2 incubator by infusing N2 into the sub-chamber until it reaches the set point and thus holding it there. This allows a hypocapnia experiment without disturbing other cultures.

CONTROL GAS IS OXYGEN

Setpoints are 20.9-99.9% oxygen. The higher the set point, the more time and oxygen it takes to reach and hold the setpoint.

Hypercapnia is a relative term that means excess concentration of CO2. The ProOx C21 can create hypercapnia by infusing the CO2 into the chamber until it reaches the setpoint and holding it there.

ELECTRICAL POWER: 12 VDC at 2.5A

CONTROL RANGE: 0.1-99.9% oxygen, 0.1-20% carbon dioxide

ACCURACY: O2: ±1% at constant temperature/pressure ±2% over entire temperature range. CO2: .1% or 5% of measurement, whichever is greater.

RESOLUTION: 0.1%

OXYGEN SENSOR: Various application specific sensors available.

GAS SOURCE: compressed gas tanks, liquid carboys (from headspace), or generators.

GAS SUPPLY: pressurized CO2, O2, and/or N2

GAS SUPPLY LINE: 1/8 inch I.D. hose, pressure rated to 25 PSIG.

GAS SUPPLY LINE PRESSURE: 1-25 PSIG

GAS INFUSION RATE: 1-14 S.C.F.H.

GAS CONSUMPTION: depends on (1) size and leakiness of host chamber, (2) frequency and duration of opening chamber doors, and (3) oxygen level controlled.

GAS SUPPLY HOSE FITTING: 1/8” hose barb.

UMBILICAL LENGTH: 12 Ft. (custom lengths available).

SENSOR CABLE LENGTH: 12 Ft.

SENSOR CABLE DIAMETER: 6mm.

ALARM OUTPUT: audible 40dB and visible flashing indicator.

ALARM MODES: process high, process low, deviation high, deviation low, deviation band.

WEIGHT: 2.2lbs (Controller Only)

DIMENSIONS: 2.5”H x 8”W x 7”D (Controller Only)

Sensor Operational Parameters

HOST CHAMBER TEMPERATURE: 5-40°C (depending on sensor)

HOST CHAMBER CO2: 0.1-20% (depending on sensor)

HOST CHAMBER HUMIDITY: 5-95% RH. Non-Condensing

Front Panel

1. Bleed Barbs: Used in calibration. Calibration cup for sensor attaches here.

2. Bleed Valves: bleeds gases out of gas supply lines.

3. Controller: bright blue digits on black back ground. Continuously displays current control gas level, control status, and alarm status in all chambers. Displays menu items and settings during programming.

4. Gas Switch: Manually overrides controller to shut off gas.

5. Alarm Switch: Manually overrides controller to shut off alarm.

6. Cal Gas Input: This barb is for calibration purposes.

Back Panel

7. Power Receptacle: 12VDC power supply connects here.

8. Communications Cables: These cables relay information for the sensors and give power to the sample draw pump.

9. Connecting Infusion Tubes: Attach the 1/16 inch ID infusion tubes to the “CAL” N2/O2 and CO2.

10. Supply Gas Hose Barb: Barbs for 1/4 inch I.D. hose from gas sources. Handles pressure up to 25 PSIG.

11. RS 485 Connections: One cable attaches to a computer and the other cable attaches to another unit, to allow communication with the computer (if applicable).

Altitude / Aerospace

Blood / Hematology

Cancer / Tumor Biology

Carbon Monoxide

Cardiovascular

Cell Analysis

Cell Cycle / Cell Death

Cell Imaging

Circadian Rhythm

Development

Endocrine / Diabetes

Exercise

Gastrointestinal

Genetics / Genomics

Hepatocyte

HIF / Hypoxia

Hypercapnia

Immunology

In Vitro Drug Discovery

In Vitro Toxicology

Intermittent Hypoxia

Kidney

Metabolism / Mitochondria

Neuroscience

Nitric Oxide

Orthopaedic / Musculoskeletal

Oxygen Sensing

Pulmonary

Physiologic Oxygen / Physioxia

Redox / ROS / Oxidative Stress

Respiratory Control / Therapeutic Hypoxia

Sleep Apnea

Stem Cell

Tissue Engineering / 3D Culture / Organoid

Vascular Research

Vision / Ophthalmology

Forgalmazott termékeink gyártói - keressen gyártó szerint a logóra kattintva

Forgalmazott termékeink gyártói - keressen gyártó szerint a logóra kattintva